Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: HY2000A/HY2500A/HY2700A/3400A

Brand: QIUXUE

Place Of Origin: China

Types Of: Synthetic Resin And Plastics

RELATED VISCOSITY: 2.45

Color: Raw White

Packing: 25kgs Or 800kgs Jumbo Bag

Packaging: THE INNER LAYER IS ALUMINUM FOIL AND THE OUTER LAYER IS PP OR KRAFT BAGS.

Productivity: 30000 TONS PER MONTY

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Supply Ability: 350,000 TONS PER YEAR

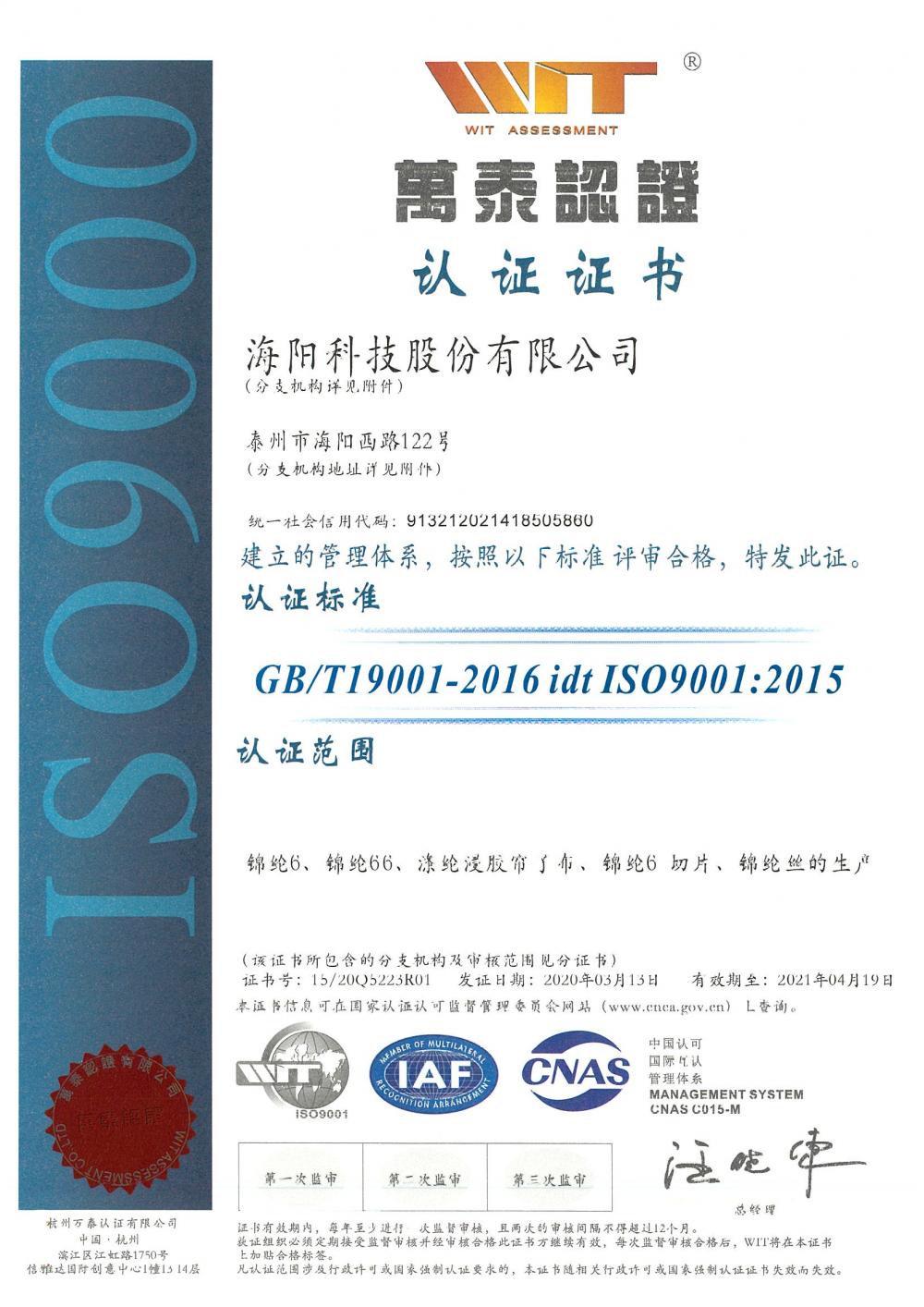

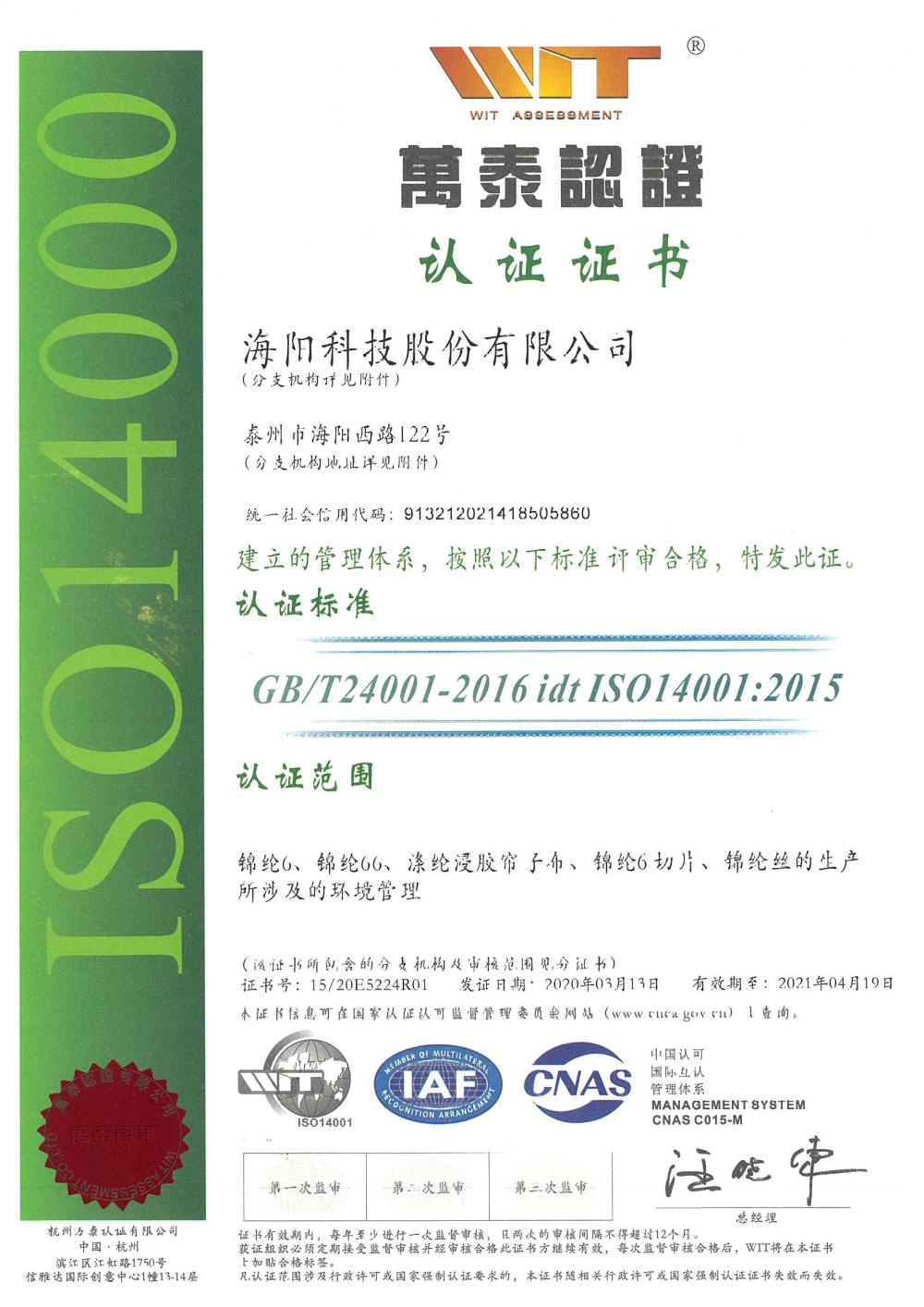

Certificate: ISO9000,ISO14001

HS Code: 390810

Port: SHANGHAI,TAICANG,ZHANGJIAGANG

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Nylon 66 Material has a higher melting point among polyamide materials. Nylon 66 is a semi-crystalline crystalline material. PA66 also maintains strong strength and stiffness at higher temperatures. PA66 plastic remains hygroscopic after molding, the extent of which depends mainly on material composition, wall thickness and environmental conditions. In product design, the effect of hygroscopicity on geometric stability must be considered. In order to improve the mechanical properties of PA66, various modifiers are often added. Glass is the most common additive, and synthetic rubber is sometimes added to improve impact resistance. Nylon 66 tubing is less viscous and therefore flows better (but not as good as PA6). This property can be used to handle very thin components. Its viscosity is sensitive to temperature changes. The shrinkage of PA66 is between 1% and 2%. Adding glass fiber additives can reduce the shrinkage to 0.2%~1%. The shrinkage in the flow direction and perpendicular to the flow direction is quite different. Thermal Properties of Polyamide Nylon 66 Melting point is the temperature at which the crystals melt. For the crystalline polymer PA66 plastic, it shows a well-defined melting point. Depending on the test method used, the melting point fluctuates from 259 to 267°C. The melting point of PA66 plastic, usually measured by differential thermal analysis, is 264°C. The melting point temperature of nylon 66 is 246 to 263° C. when the temperature at which the volume expansion coefficient shows a maximum value is taken as the melting point. Close to the theoretical melting temperature of 259°C. Injection molding characteristics of PA66 plastic drying treatment: If the material is sealed before processing, drying is not required. However, if the storage container is open, drying in hot air at 85°C is recommended. If the humidity is greater than 0.2%, vacuum drying at 105°C for 12 hours is required.

| NO | ITEM | NORM | DATA |

| 1 | VISCOSITY | Q/321200WLB001—2019 | M±0.04 |

| 2 | MONOMER CONTENT(% ) | Q/321200WLB001—2019 | ≤0.6 |

| 3 | MOISTURE CONTENT(% ) | Q/321200WLB001—2019 | ≤0.06 |

| 4 | AMINE END GROUPS(Meg/kg) | Q/321200WLB001—2019 | 40±3 |

Product Categories : Nylon 6 Chips > Bright Nylon 6 Chips

BRIGHT NYLON6 CHIPS IS WIDELY USED IN ENGINEERING PLASTIC AND TEXTILE GRADE.ITS VISCOSITY IS FROM 2.0 TO 3.8.ITS ADVANTAGE IS GOOD APPEARANCE, GOOD SPINNING ABILITY,HIGH STRENGTH AND HIGH DYEING PERFORMANCE.WE PRODUCE THE PRODUCT VIA HIGH HIGH-END LIQUID MATERIALS WHICH IS IMPORTED FROM USA, JAPAN, THE NETHERLANDS, ETC., WITH VK CONTINUOUS POLYMERIZATION, UNDERWATER GRANULATION, CONTINUOUS AIRFLOW DRYING, DCS CONTROL AND OTHER TECHNOLOGIES.THE AMINO TERMINAL GROUP, MONOMER CONTENT AND OTHER SPECIFICATION ARE BETTER.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.