Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: HY2500

Brand: QIUXUE

Place Of Origin: China

Types Of: Synthetic Resin And Plastics

RELATED VISCOSITY: 2.45

Color: Raw White

Packing: 25kgs Or 800kgs Jumbo Bag

Packaging: THE INNER LAYER IS ALUMINUM FOIL AND THE OUTER LAYER IS PP OR KRAFT BAGS.

Productivity: 30000 TONS PER MONTY

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Supply Ability: 350,000 TONS PER YEAR

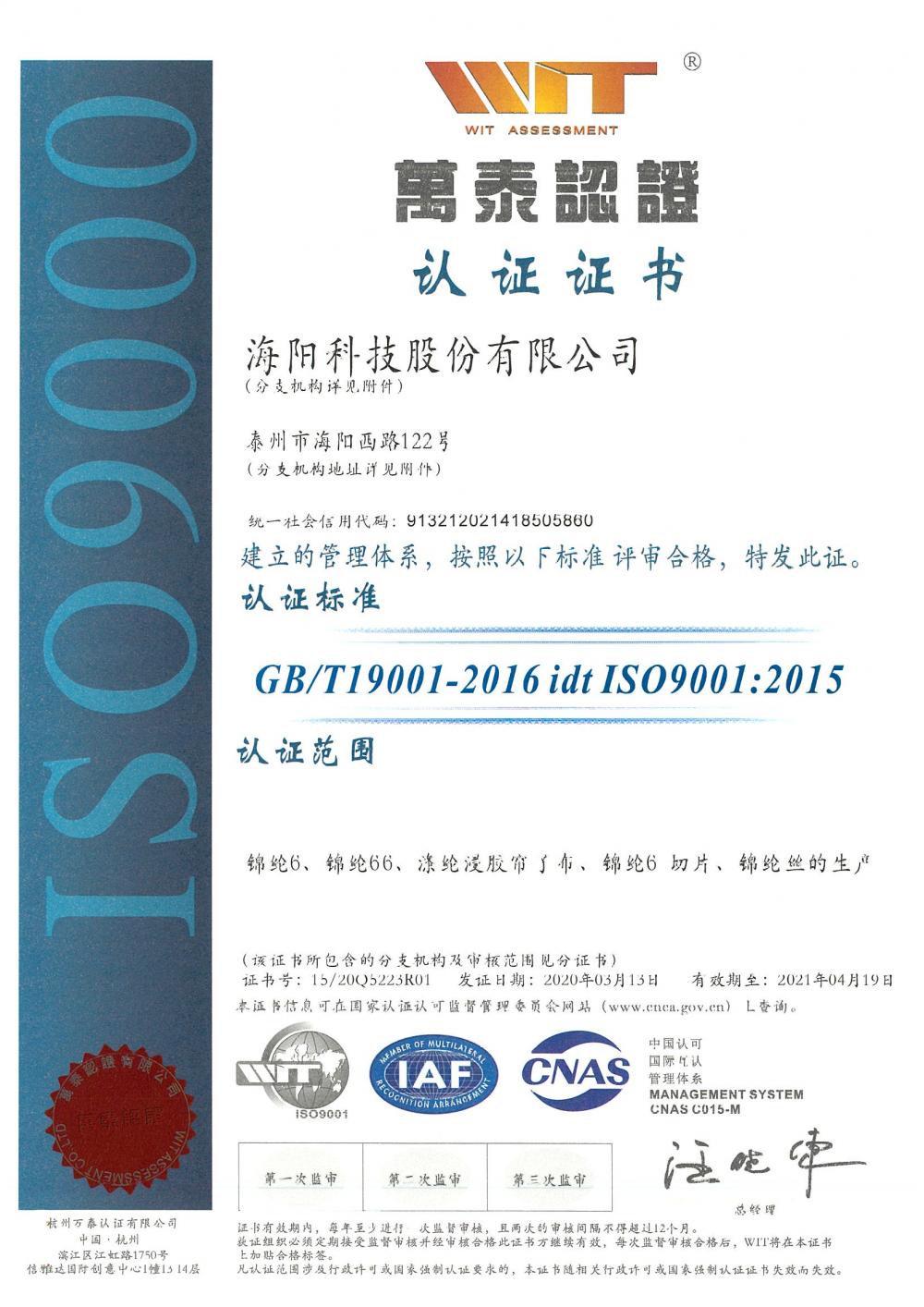

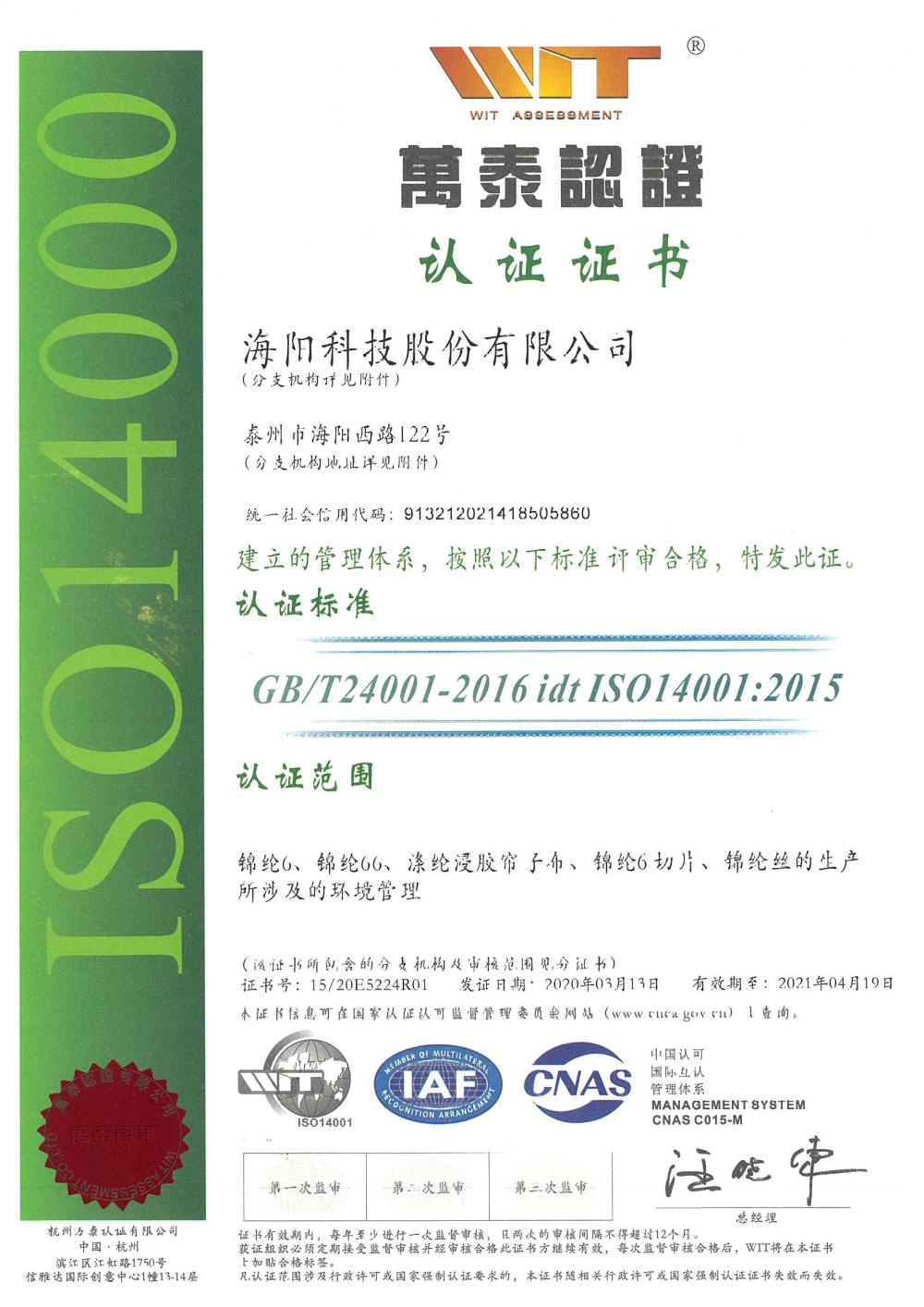

Certificate: ISO9000,ISO14001

HS Code: 390810

Port: SHANGHAI,TAICANG,ZHANGJIAGANG

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Because Nylon Pa6 is easy to absorb moisture, special attention should be paid to drying before processing. If the Nylon 66 Material is supplied in a waterproof material package, the device should remain sealed. If the humidity is greater than 0.2%, it is recommended to dry in hot air above 80°C for 16 hours. If the Nylon material is exposed to air for more than 8 hours, vacuum drying at 105°C for more than 8 hours is recommended.

Melting temperature:

230-280°C, 250-280°C for enhanced varieties.

Mold temperature:

80-90 ℃, the mold temperature significantly affects the crystallinity, and the crystallinity affects the mechanical properties of the plastic parts. Crystallization of structural components

The degree of temperature is important, so the recommended mold temperature is 80-90°C. Higher mold temperatures are also recommended for thin-walled, long-running plastic parts. Increase

Higher mold temperatures can increase the strength and stiffness of plastic parts, but reduce toughness. If the wall thickness is greater than 3mm, it is recommended to use a low temperature of 20-40℃

mold. For Polyamide Nylon 6 materials, the mold temperature should be above 80°C.

| NO | ITEM | NORM | DATA |

| 1 | VISCOSITY | Q/321200WLB001—2019 | M±0.04 |

| 2 | MONOMER CONTENT(% ) | Q/321200WLB001—2019 | ≤0.6 |

| 3 | MOISTURE CONTENT(% ) | Q/321200WLB001—2019 | ≤0.06 |

| 4 | AMINE END GROUPS(Meg/kg) | Q/321200WLB001—2019 | 40±3 |

Product Categories : Nylon 6 Chips > Semi Dull Nylon 6 Chips

BRIGHT NYLON6 CHIPS IS WIDELY USED IN ENGINEERING PLASTIC AND TEXTILE GRADE.ITS VISCOSITY IS FROM 2.0 TO 3.8.ITS ADVANTAGE IS GOOD APPEARANCE, GOOD SPINNING ABILITY,HIGH STRENGTH AND HIGH DYEING PERFORMANCE.WE PRODUCE THE PRODUCT VIA HIGH HIGH-END LIQUID MATERIALS WHICH IS IMPORTED FROM USA, JAPAN, THE NETHERLANDS, ETC., WITH VK CONTINUOUS POLYMERIZATION, UNDERWATER GRANULATION, CONTINUOUS AIRFLOW DRYING, DCS CONTROL AND OTHER TECHNOLOGIES.THE AMINO TERMINAL GROUP, MONOMER CONTENT AND OTHER SPECIFICATION ARE BETTER.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.